How the SBI results are calculated?

What parameters does the SBI testing setup measure according to the normative requirements?

- Humidity is measured in the range of 20-80% ± 5%.

- Ambient temperature: the thermocouple is located near the exit of the measurement trolley, close to the floor.

- Ambient pressure with an accuracy of ±200 Pa.

- Light beam attenuation measurement system: it consists of a stabilizing structure, a light source with a colour temperature of 2900K ±100K, a lens system, and a detector.

- O2 level is measured by a paramagnetic analyser with a minimum resolution of 0.01%.

- CO2 level is measured by an infrared (IR) analyser with a minimum resolution of 0.01%.

- Flue gas velocity: measurement is carried out using a bi-directional probe and a pressure transducer.

- Flue gas temperature: measured by three thermocouples placed in the flue gas measurement pipe.

What parameters does the measurement system calculate at the SBI test, and what do they signify in relation to a real fire?

THR600s – this parameter describes the total heat released by the sample during the first 600 seconds of the test. This parameter allows to estimate the impact a particular material will have on fire development. For example, it indicates whether igniting the material will cause the fire to spread to other materials or if the released energy is sufficient to initiate or sustain the combustion process.

FIGRA – this parameter describes the rate of heat release by the tested material. It allows to estimate how quickly the material will propagate fire. In combination with the THR parameter, it enables the estimation of the likelihood and speed of fire growth.

SMOGRA – this parameter describes the rate of smoke generation by the material involved in the fire. It is particularly important for public utility buildings, production halls, and warehouses. It allows the estimation of the time after which evacuation of a room will become impossible due to smoke.

TSP600s – this parameter indicates the amount of smoke generated during the first 600 seconds of the test. It allows the estimation of whether the emitted smoke quantity during a fire will reduce visibility. This information is crucial for determining evacuation routes and hazard zones.

How are the individual parameters calculated?

The measurement system of the SBI test records the values of each measured parameter every 3 seconds throughout the entire measurement procedure. Subsequently, it calculates the primary parameters, namely:

HRR(t) – Heat Release Rate index, SPR(t) – Smoke Production Rate index.

To calculate the HRR index, the system calculates:

V298(t) – volumetric flow rate in the measurement pipe,

(t) – oxygen depletion coefficient,

xa_O2 – mole fraction of oxygen in the environment, including water vapor.

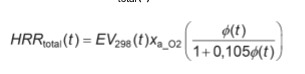

Based on the equation provided, the parameter HRRtotal(t) is calculated.

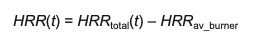

Subsequently, thanks to the auxiliary burner’s operation, it is possible to calculate the parameter HRR of the burner itself (HRRav_burner), which represents the average HRRtotal during the period of 210-270 seconds of the test. By subtracting the HRRav_burner from the total HRR during the sample burning, the HRR parameter specific to the sample can be obtained.

Based on the above calculation, the final parameter, THR600s, is calculated using the formula:

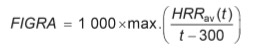

Also, based on the HRR(t) parameter, the FIGRA is calculated. This parameter is divided into two ranges: 0.2 MJ, which means it is measured when the conditions HRRav(t)>3 kW and THR(t)>0.2 MJ are met, and 0.4 MJ, which means the conditions HRRav(t)>3 kW and THR(t)>0.4 MJ are met.

This parameter is measured during the entire exposition to the sample and is calculated using the formula as follows:

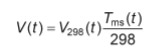

The next parameters calculated by the measurement system are TSP600s and SMOGRA. Due to the fact that the density of smoke varies with temperature during the test, the first step in calculating the smoke parameters is to determine the velocity at which air flows in the measurement system. The following formula is used for this purpose, utilizing the volumetric flow rate (V298) calculated at a temperature of 298 K and the average temperature of smoke in the measurement pipe:

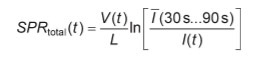

Next, the smoke production rate SPRtotal(t) is calculated using the formula:

Similarly, to the HRR calculations, it is necessary to separate the smoke parameter SPRtotal into two components: the smoke generated from the tested sample and by the burner itself. This separation is performed during the operation of the auxiliary burner and is expressed as the sum of the following terms:

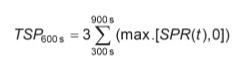

Once we have obtained the parameter SPR(t), which represents the smoke generated by the sample alone, we can calculate the value for TSP600s using the following equation:

Once we have obtained the parameter SPR(t), which represents the smoke generated by the sample alone, we can calculate the value for TSP600s using the following equation: