How is the SBI test conducted?

How is the SBI test conducted?

According to the SBI method, the test involves subjecting a corner-shaped sample with dimensions of height 1500mm and wing lengths: short (500mm) and long (1000mm), exposed to the 32.4 kW fire flame of a sand burner.

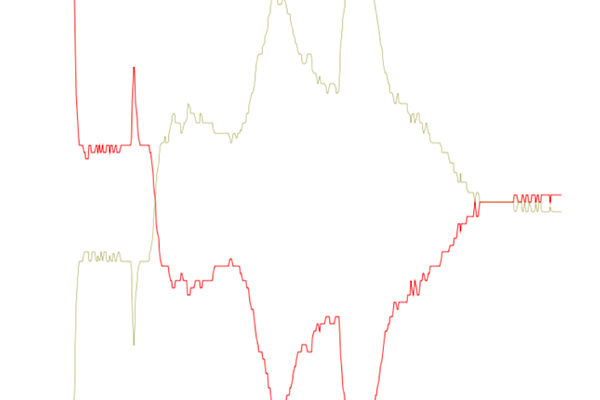

View of the testing facility

Description of the testing facility

The detailed construction of the equipment is described in the EN 13823 standard. The SBI equipment consists of three main sections: the testing chamber, the measurement trolley, and the flue gas analysis section.

The testing chamber is constructed using fire-resistant materials and has internal dimensions of 3x3m and a height of 2.4m. It has an entrance for the operator and allows for walking on the roof, where the flue gas analysis section is located. The sand burner, identical to the one on the measurement trolley, is installed in the chamber. It serves as the background burner, and its role is described further in the text.

The measurement trolley is built on a mobile, steel frame. The sample and bottom plates, used for creating the so-called “air gap,” are installed on the measurement trolley. The methods of sample installation are described in a separate article.

The flue gas analysis section is the most complex part of the testing setup. It includes temperature sensors, an analyser for measuring the O2 and CO2 content in the flue gases, a pressure difference sensor for measuring the velocity of the flue gases, a fan with adjustable performance, and a system for measuring light beam attenuation.

Testing Procedure

To conduct the test, the material sample is placed on the measurement trolley.

View of the sample ready for testing.

A sand burner that generates a 32.4 kW fire flame during the measurement procedure, is located in the lower corner of the sample.

After introducing the sample into the testing chamber, the actual measurement procedure begins, consisting of the following stages:

- Environmental conditions measurement – the standard precisely describes the required conditions for the test. If they are not met, the measurement has to be suspended.

- Initial conditions measurement – during this stage, the system reads and calculates the averages of parameters such as O2 and CO2 content, ambient temperature, air temperature in the measurement channel, humidity, pressure, and light intensity over a period of 3 minutes.

- Operation of the auxiliary burner – the auxiliary burner installed in the testing chamber operates for the next 3 minutes. During its operation, the burner power and the amount of generated smoke are recorded. The parameters calculated during this stage are described later in the article.

- Main exposition of the sample to fire – the tested sample is exposed to fire for 20 minutes. During this stage, parameters necessary for the classification are measured, including THR (Total Heat Release), SPR (Smoke Production Rate), FIGRA (Fire Growth Rate), and SMOGRA (Smoke Growth Rate).

- Waiting time for sample extinction – after the exposition, the sample in the testing chamber should extinguish completely and stop emitting heat and smoke. The standard allows for manual extinguishment of the sample by the operator.

- Measurement of final conditions – after the sample has been extinguished, the parameters necessary for calculating the analyser drift and the light beam attenuation drift are measured.

Calculation of classification parameters:

THR600s (Total Heat Release) – this parameter represents the total amount of heat released by the sample during the first 10 minutes (600 s) of exposition. It is calculated based on the sum of the parameter HRR(t).

FIGRA0.2MJ – this parameter describes the heat release rate by the sample, measured when THR(t) > 0.2 MJ, meaning if the sample releases more heat than 0.2 MJ at a given moment.

FIGRA0.4MJ – this parameter describes the heat release rate by the sample, measured when THR(t) > 0.4 MJ, meaning if the sample releases more heat than 0.4 MJ at a given moment.

TSP600s – this parameter describes the total amount of smoke produced during the first 600 seconds of exposition. It is calculated based on the sum of the parameter SPR(t).

SMOGRA – the maximum smoke generation rate by the sample during the entire exposition.